HYDRAULIC BOTTLE JACK Manufacturer in China

We manufacture reliable HYDRAULIC BOTTLE JACKS designed for vehicle lifting, industrial maintenance, and heavy-duty applications. Built with strong steel bodies and stable hydraulic systems, our jacks deliver safe lifting power for workshops, roadside service, and equipment fleets.

What We Offer as a HYDRAULIC BOTTLE JACK Manufacturer in China

As a leading HYDRAULIC BOTTLE JACK manufacturer in China, we supply a wide range of lifting capacities from 2T to 50T. Our products are built for automotive repair shops, fleet maintenance teams, construction sites, and tool brands seeking reliable lifting equipment for global distribution.

We offer complete OEM/ODM customization including lifting height, capacity, base plate size, hydraulic performance, safety valves, bottle design, painting colors, brand labeling, and export packaging. Whether you need compact jacks for roadside kits or industrial bottle jacks for heavy machinery, we deliver stable quality with competitive factory pricing.

Product List

Services We Provide

HYDRAULIC BOTTLE JACK

OEM/ODM Capacity Customization

Custom tonnage, stroke height, hydraulic pump structure, and cylinder dimensions.

Branding Options

Custom color painting, logo stamping, product labels, and retail packaging.

Industrial-Grade Enhancements

Thicker base plate, reinforced cylinder, stronger seals, and upgraded pressure valves.

Bulk Production for Global Markets

Large-scale manufacturing suitable for wholesalers, retailers, and private-label brands.

Why Choose Us for HYDRAULIC BOTTLE JACK Manufacturing

Strict Hydraulic Pressure Testing

Each jack undergoes tonnage testing, leakage inspection, and pressure stability evaluation.

Reliable Delivery Time

Well-structured production lines ensure consistent lead times for bulk orders.

Custom Engineering for Special Markets

We tailor tonnage, height, and pressure systems for various regional requirements.

Factory-Direct Competitive Pricing

Ideal for distributors seeking strong cost control and high-value performance.

Long-Term Component Support

Seals, pistons, handles, and valves available for long-term maintenance needs.

Work With a Trusted HYDRAULIC BOTTLE JACK Manufacturer in China

Get OEM/ODM bottle jacks engineered for reliable lifting performance, durable construction, and competitive pricing.

Frequently Asked Questions

01. What lifting capacities do you offer?

Our standard range includes 2T, 4T, 6T, 8T, 10T, 12T, 20T, 30T, and 50T.

02. Can I customize the height or stroke?

Yes. We can modify minimum height, maximum height, and lifting stroke based on your needs.

03. Do you support private-label production?

Absolutely. Custom colors, logos, labels, and packaging are all supported.

04. Are your bottle jacks suitable for trucks?

Yes. High-tonnage models are designed for trucks, vans, and industrial equipment.

05. How long is the manufacturing lead time?

Usually 20–30 days depending on quantity and customization.

Table of Contents

HYDRAULIC BOTTLE JACK: A Complete Guide to Lifting Safety and Workshop Use

Product Overview of Hydraulic Bottle Jack

A hydraulic bottle jack is a compact lifting tool widely used for vehicle repair, construction work, and heavy-duty industrial applications. Its strong lifting capacity and portable design make it one of the most practical lifting devices for workshops and emergency roadside use.

What Is a Hydraulic Bottle Jack?

A hydraulic bottle jack is a high-force lifting tool that uses hydraulic pressure to raise heavy loads. With its bottle-shaped steel body and pump handle, it provides strong lifting force in a small, portable structure. It is suitable for cars, trucks, machinery, and equipment maintenance.

Types of Hydraulic Bottle Jack

- Standard Hydraulic Bottle Jack

Most common type, used for vehicle maintenance.

- Heavy-Duty Industrial Bottle Jack

Designed for trucks, construction equipment, and industrial lifting.

- Low-Profile Bottle Jack

Used for vehicles with small ground clearance.

- Double-Ram Bottle Jack

Provides higher maximum height for tall vehicles.

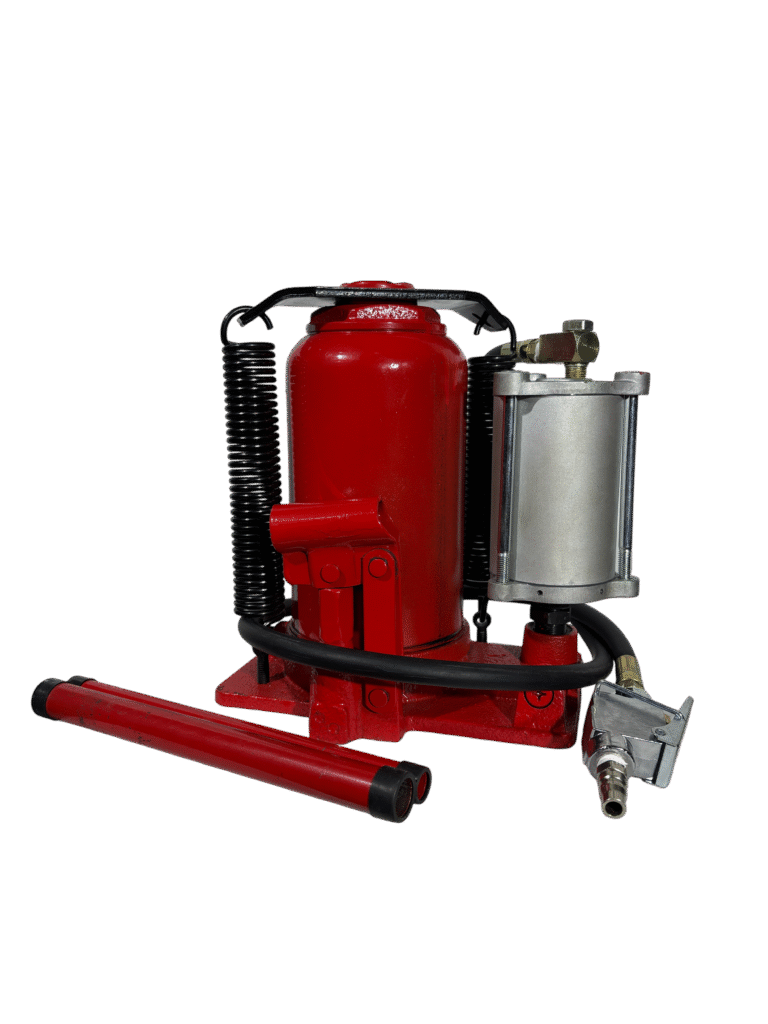

- Air/Hydraulic Bottle Jack

Operates using pneumatic power for faster lifting.

Key Features & Advantages

- High lifting capacities (2–50 tons)

- Strong steel cylinder for durability

- Compact size for easy storage and portability

- Stable hydraulic pressure and safety valve

- Simple operation with manual pump handle

- Suitable for workshops, roadside kits, and industrial sites

Common Applications

Hydraulic bottle jacks are used in:

- Automotive repair shops

- Roadside emergency kits

- Industrial maintenance

- Agricultural machinery service

- Fleet and logistics maintenance

- Construction equipment support

How to Choose the Right Hydraulic Bottle Jack

Consider the following factors:

- Lifting Capacity (Tonnage)

Choose a jack that exceeds the weight of the target vehicle or equipment.

- Minimum and Maximum Height

Ensure it fits under the vehicle and reaches required lifting height.

- Single-Ram vs. Double-Ram

Double-ram models reach higher with fewer pumps.

- Durability & Seal Quality

High-quality seals prevent oil leakage and pressure loss.

- Base Plate Size

Wider bases offer better stability.

- Safety Features

Look for overload valves and reinforced steel body structures.

Installation & Operation Tips

- Place the jack on a stable, level surface

- Engage the vehicle’s parking brake

- Position the jack under the designated lifting point

- Pump the handle smoothly to raise the load

- Always use jack stands for long-duration support

- Lower the load slowly and steadily

Maintenance & Troubleshooting

Routine Maintenance

- Check hydraulic oil level

- Inspect seals for leaks

- Keep the pump clean and lubricated

- Store upright to prevent air entering the system

Troubleshooting

- Low lifting power: check oil level or bleed air

- Oil leakage: replace worn seals

- Handle resistance: lubricate pivot points

- Jack not raising: ensure release valve is fully closed

Safety Considerations

- Never exceed rated tonnage

- Always use jack stands—never rely solely on the jack

- Keep hands clear during lifting and lowering

- Use on solid, stable ground

- Do not tilt or place the jack on uneven surfaces

Conclusion

Hydraulic bottle jacks offer strong lifting power in a compact design, making them essential tools for automotive and industrial applications. With proper selection, maintenance, and safe operation, they deliver long-term reliability and performance for professional workshops and vehicle owners.