SHOP CRANE Manufacturer in China

We manufacture durable SHOP CRANES designed for engine removal, equipment lifting, and heavy-duty workshop operations. Featuring stable frames, foldable designs, and high-capacity hydraulic systems, our shop cranes deliver reliable lifting performance for repair shops and service centers.

What We Offer as a SHOP CRANE Manufacturer in China

As a professional SHOP CRANE manufacturer in China, we supply engine cranes engineered for lifting engines, machinery parts, and heavy components in automotive workshops. Our product range includes foldable cranes, fixed-frame cranes, long-boom models, and high-capacity hydraulic versions.

We provide full OEM/ODM customization covering boom length, lifting capacity, hydraulic cylinder performance, steel thickness, caster design, coating color, logo branding, and packaging. Whether serving tool brands, distributors, or equipment wholesalers, we deliver high-strength shop cranes built for global workshop standards with competitive pricing and consistent quality.

Product List

Services We Provide

SHOP CRANE

OEM/ODM Custom Engineering

Custom load rating, boom length, cylinder type, wheel style, and steel thickness.

Branding Support

Custom paint color, brand logo, stickers, manuals, and private-label packaging.

Performance Upgrade Options

Upgraded hydraulic cylinders, heavy-duty casters, reinforced joints, and long-reach booms.

Bulk Manufacturing Capacity

Stable, high-volume output suitable for tool distributors and equipment suppliers.

Why Choose Us for SHOP CRANE Manufacturing

Strict Load & Structural Testing

Every crane undergoes load simulation, welding inspections, and hydraulic pressure checks.

Reliable Lead Times for OEM Orders

Fast production and stable supply for large-volume international shipments.

Engineering Support for Custom Requirements

We optimize boom geometry, lift height, and frame structure for your market.

Competitively Priced Factory Manufacturing

Strong cost advantage for distributors targeting professional repair shops.

Long-Term Spare Parts Availability

Hydraulic cylinders, casters, booms, and pins supported for long-term maintenance.

Work With a Trusted SHOP CRANE Manufacturer in China

Get OEM/ODM shop cranes engineered for safe lifting performance, durable construction, and competitive pricing.

Frequently Asked Questions

01. What lifting capacities do you offer?

Common options include 1T, 2T, and 3T, with OEM custom tonnage available.

02. Do you provide foldable engine cranes?

Yes. Foldable shop cranes are available for compact storage in workshops.

03. Can I customize color and branding?

Yes. OEM colors, logos, safety labels, and packaging are all supported.

04. Are your shop cranes suitable for engine removal?

Yes. All cranes are designed for safe and stable engine lifting and installation.

05. What is the typical lead time?

20–30 days depending on quantity and customization.

Table of Contents

SHOP CRANE: A Complete Guide to Engine Lifting and Workshop Operations

Product Overview of Shop Crane

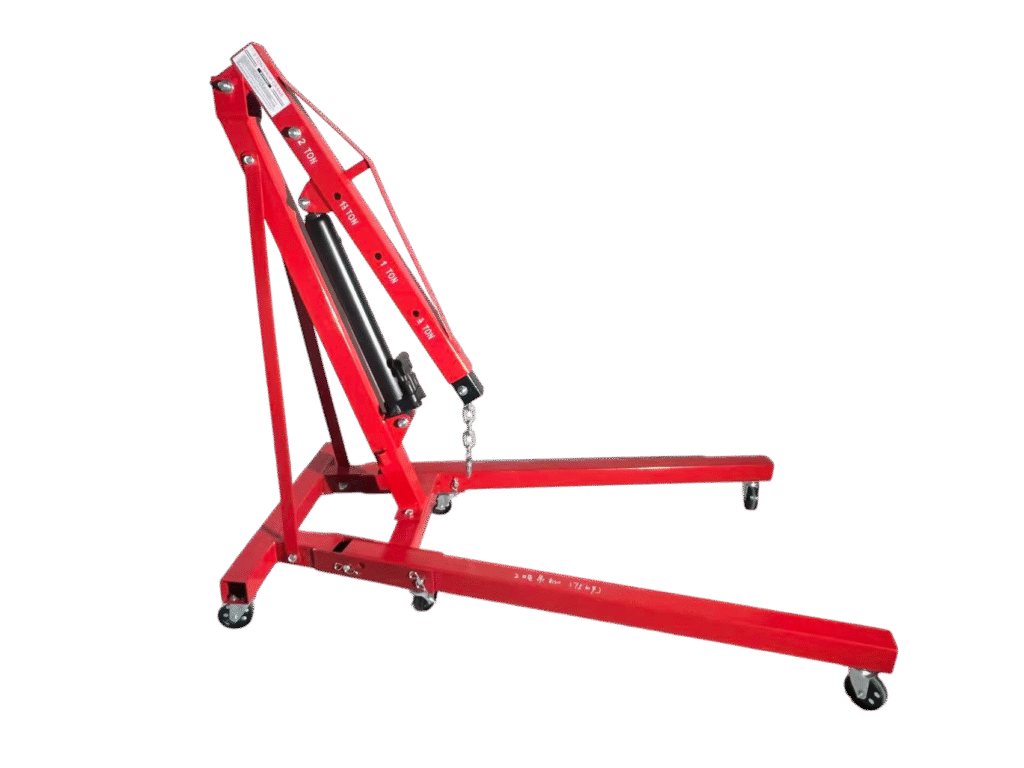

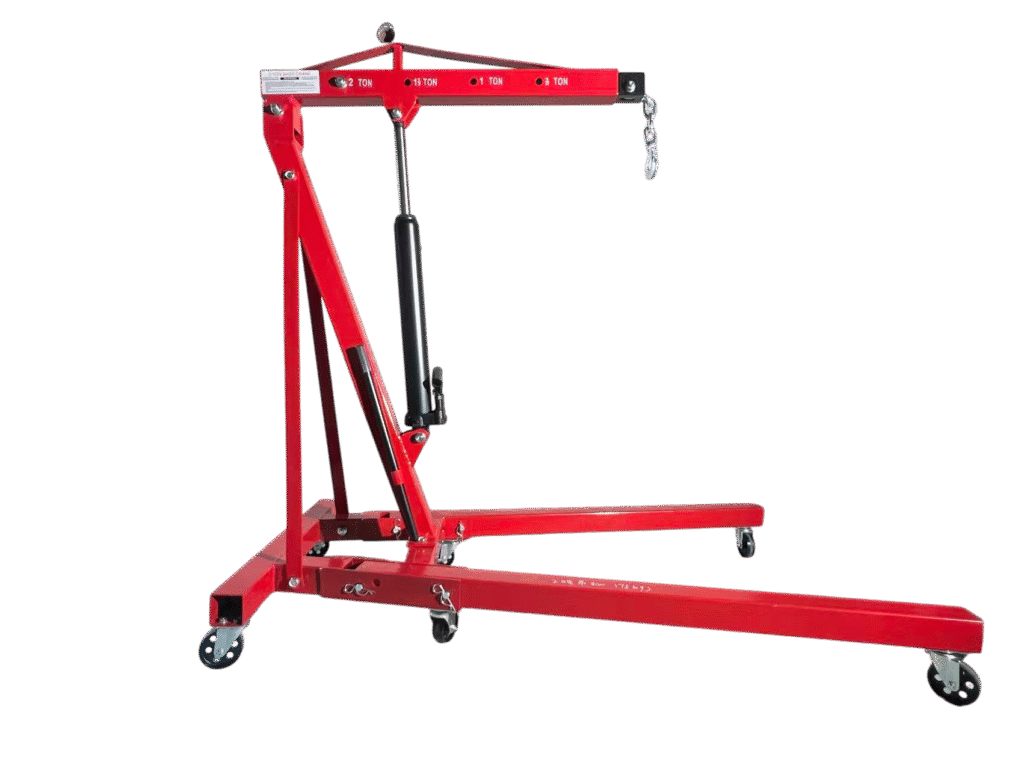

A shop crane—also known as an engine crane or engine hoist—is a hydraulic lifting tool designed for removing and installing engines, lifting machinery components, and handling heavy workshop loads. It improves efficiency and ensures safe, controlled lifting for professional mechanics.

What Is a Shop Crane?

A shop crane is a wheeled hydraulic lifting device consisting of a steel frame, extendable boom, and hydraulic cylinder. It lifts heavy loads vertically and allows technicians to maneuver engines or equipment safely within a workshop. Many models feature folding frames for easier storage.

Types of Shop Crane

- Foldable Shop Crane

Space-saving design ideal for small workshops.

- Fixed-Frame Shop Crane

Heavier structure for continuous lifting tasks.

- Long-Arm/Long-Boom Crane

Extended reach for large vehicles or machinery.

- Heavy-Duty Shop Crane

Higher capacities for truck engines and industrial applications.

- Portable Mini Cranes

Compact designs for mobile service teams.

Key Features & Advantages

- High lifting capacity (1–3 tons)

- Stable hydraulic system with controlled lifting

- Adjustable boom for various lifting ranges

- Reinforced steel frame for long-term durability

- Smooth-rolling casters for mobility

- Optional foldable structure for easy storage

Common Applications

Shop cranes are widely used for:

- Removing and installing automotive engines

- Lifting transmissions and heavy parts

- Machinery maintenance and assembly

- Workshop equipment handling

• Industrial repair and fabrication operations

How to Choose the Right Shop Crane

- Load Capacity

Select based on engine size—1T for small cars, 2–3T for larger engines.

- Boom Length & Adjustment Levels

Longer boom = better reach but lower capacity at full extension.

- Foldable vs. Fixed Frame

Foldable for small workshops, fixed for heavy, frequent lifting.

- Hydraulic Cylinder Quality

Stronger cylinders ensure smooth, safe lifting under full load.

- Caster Type

Choose steel or heavy-duty swivel casters for smooth movement.

- Frame Material & Thickness

Thicker steel increases stability and service life.

Installation & Operation Tips

- Inspect frame, pins, and hydraulic cylinder before each use

- Adjust boom length according to load weight

- Ensure casters are stable before lifting

- Attach the load securely using a proper lifting chain

- Pump slowly and maintain control at all times

- Move the crane carefully with the load lifted minimally

Maintenance & Troubleshooting

Routine Maintenance

- Check hydraulic oil level

- Lubricate pivot points and hinges

- Inspect casters for wear

- Tighten bolts and joints regularly

Troubleshooting

- Slow lifting: check oil level or bleed air

- Hydraulic leak: replace seals or inspect cylinder

- Boom instability: ensure locking pins are fully engaged

- Caster resistance: lubricate wheels or replace bearings

Safety Considerations

- Never exceed the crane’s rated load capacity

- Keep lifting chain and hooks in good condition

- Lift smoothly—avoid sudden movements

- Do not walk under a suspended load

- Use in open, stable, and clean workshop areas

- Check all locking pins before operation

Conclusion

A shop crane is a critical tool for engine handling and heavy workshop lifting. With proper selection, safe operation, and regular maintenance, it delivers long-term performance and improves safety and efficiency in automotive repair environments. For mechanics and workshop operators, a well-built shop crane is an essential investment.