SHOP PRESS Manufacturer in China

What We Offer as a SHOP PRESS Manufacturer in China

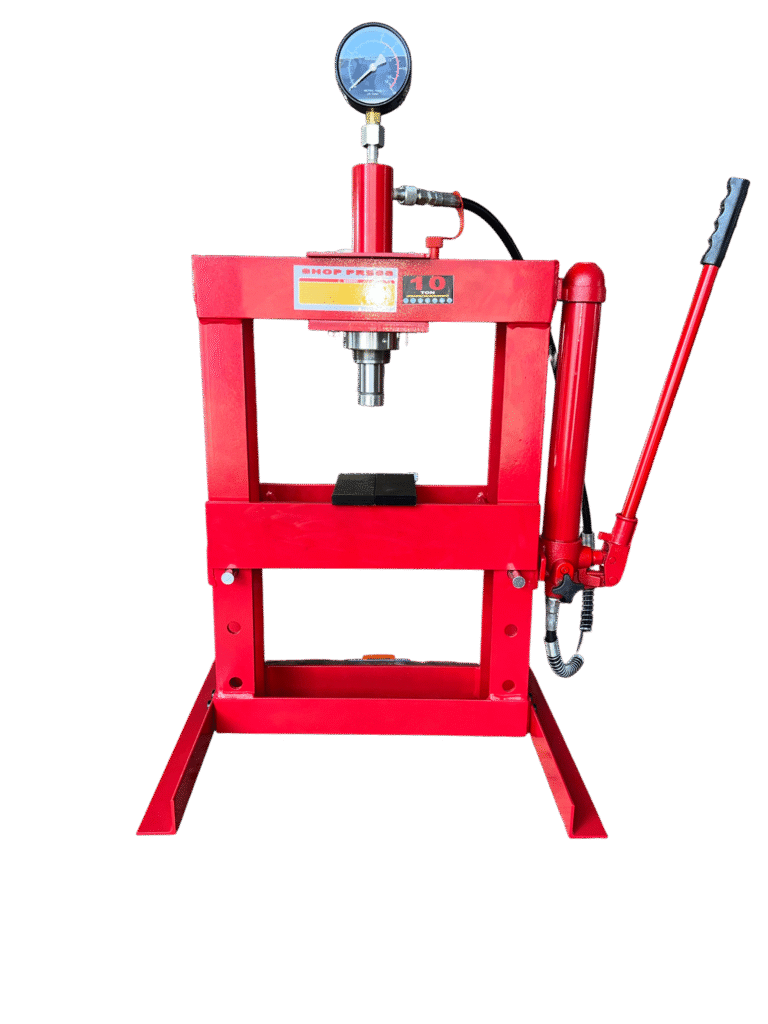

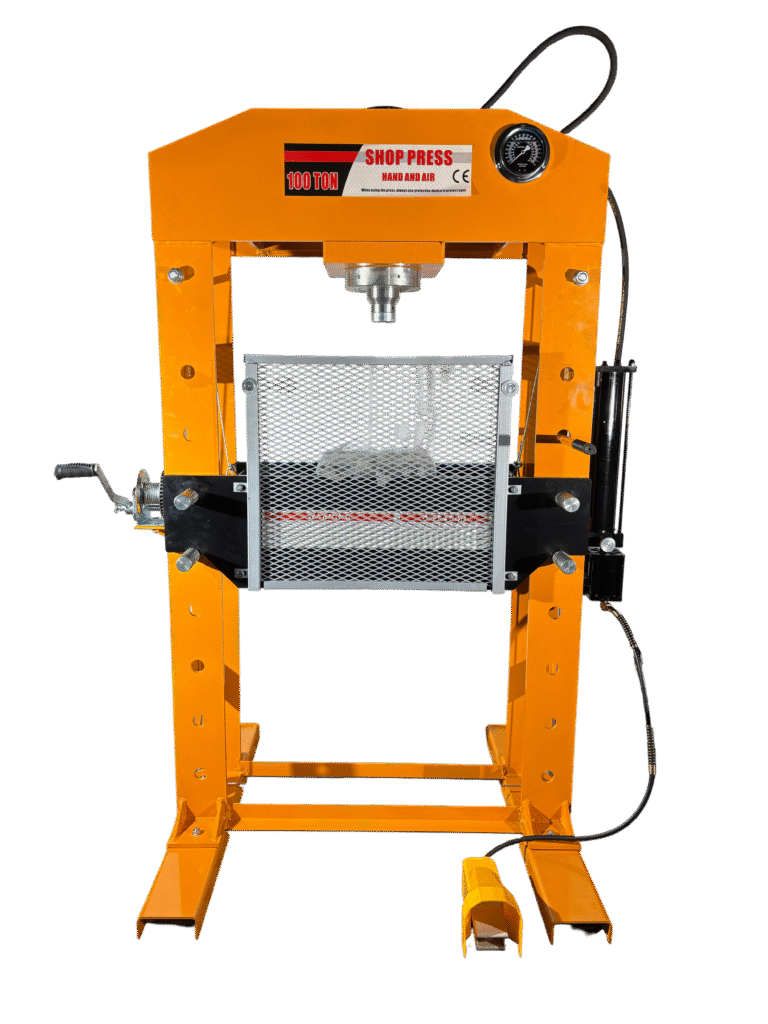

As a professional SHOP PRESS manufacturer in China, we supply hydraulic press machines commonly used for bearing installation, metal shaping, straightening, and repair work. Our product lines include 6T, 12T, 20T, 30T, and 50T workshop presses with H-frame or A-frame structures.

We provide full OEM/ODM customization covering press capacity, frame design, workbench width, cylinder type, adjustable height positions, safety shields, color coating, branding labels, and packaging. Whether you serve automotive repair shops, machinery service teams, or tool distributors, we deliver stable-quality hydraulic presses built for global workshop standards.

Product List

Services We Provide

SHOP PRESS

OEM/ODM Customization

Tonnage, cylinder style, table width, frame height, handle design, and color options.

Branding & Packaging Solutions

Logos, manuals, stickers, color coating, and export-ready packaging.

Industrial Performance Upgrades

Stronger welded frames, improved steel thickness, upgraded cylinders, and safety shields.

High-Volume Manufacturing for Global Markets

Suitable for tool brands, distributors, hardware suppliers, and workshop equipment wholesalers.

Why Choose Us for SHOP PRESS Manufacturing

Strict Pressure & Frame Testing

Each press undergoes load capacity, structural integrity, and hydraulic sealing tests.

Reliable OEM Lead Times

Fast, stable production lines ensure timely delivery for large distributor orders.

Engineering Support for Custom Models

We adjust frame structure, tonnage, table design, and cylinder setup for market needs.

Competitive Factory Pricing

High-performance shop presses with strong cost advantages for B2B buyers.

Spare Parts Support

Cylinders, handles, frames, bolts, and accessories available for long-term use.

Work With a Trusted SHOP PRESS Manufacturer in China

Get OEM/ODM shop presses engineered for professional workshop needs with strong hydraulic performance and competitive pricing.

Frequently Asked Questions

01. What capacities do your shop presses offer?

6T, 12T, 20T, 30T, and 50T, with OEM custom tonnage available.

02. Do you provide H-frame or A-frame presses?

Yes. Both designs are available depending on your market requirements.

03. Can I customize the frame color and branding?

Yes. OEM color coating, logos, labels, and packaging are fully supported.

04. Are your cylinders removable or fixed?

We offer both models: fixed cylinders and movable single-acting cylinders.

05. What is the typical lead time?

20–30 days depending on quantity and customization.

Table of Contents

SHOP PRESS: A Complete Guide to Workshop Pressing, Bending & Straightening

Product Overview of Shop Press

A shop press is an essential workshop tool used for pressing bearings, straightening metal parts, bending components, and assembling mechanical structures. With strong hydraulic force and a stable frame, it improves efficiency and precision in automotive and industrial repair environments.

What Is a Shop Press?

A shop press is a hydraulic machine that uses controlled downward force to shape, press, or straighten various materials. It typically features a steel frame, adjustable worktable, hydraulic cylinder, and manual or air-assisted pump. Shop presses are valued for their simplicity, strength, and accuracy during repair and assembly tasks.

Types of Shop Press

- H-Frame Shop Press

The most common type, offering stability and strong vertical pressing force.

- A-Frame Shop Press

Compact and rigid design suitable for smaller workshops.

- Manual Hydraulic Shop Press

Operated with a hand pump—ideal for general repair work.

- Air/Hydraulic Shop Press

Uses compressed air for faster operation in high-volume workshops.

- Heavy-Duty Industrial Press

High tonnage models designed for large machinery maintenance.

Key Features & Advantages

- Strong hydraulic pressing force (6T–50T)

- Reinforced steel frame construction

- Adjustable worktable height positions

- Smooth, controlled pressure output

- Compatibility with various dies and attachments

- Suitable for automotive and industrial applications

Common Applications

Shop presses are widely used for:

- Bearing installation and removal

- Straightening bent components

- Bending brackets or metal plates

- Press-fitting mechanical parts

- Bush, gear, and U-joint pressing

- Automotive suspension repair

- Machinery assembly work

How to Choose the Right Shop Press

- Tonnage Requirement

Choose higher tonnage for thicker, stronger, or larger components.

- Frame Type

H-frame for heavy-duty tasks, A-frame for compact environments.

- Worktable Adjustability

Multiple height positions increase versatility.

- Cylinder Type

Fixed vs. movable cylinders depending on user preference.

- Pump Style

Manual or air-assisted based on workshop volume.

- Build Quality

Look for reinforced welds, thick steel plates, and stable base design.

Installation & Operation Tips

- Place the press on a stable, level surface

- Adjust the worktable height according to your task

- Position the workpiece securely before applying force

- Pump slowly to control pressure

- Stop immediately if unusual resistance or misalignment occurs

- Use appropriate dies or press blocks

Maintenance & Troubleshooting

Routine Maintenance

- Check and refill hydraulic oil

- Inspect frame welds and bolts

- Lubricate moving parts and pins

- Clean press surfaces regularly

Troubleshooting

- Low pressure: bleed hydraulic system or refill oil

- Cylinder leak: replace seals or inspect piston

- Uneven pressing: check table alignment

- Stiff pump action: lubricate pump components

Safety Considerations

- Never exceed rated tonnage

- Keep hands clear of pressing area

- Use proper support tools and dies

- Verify stable alignment before pressing

- Avoid sudden pressure release

Conclusion

A shop press is an indispensable tool for automotive repair, machinery maintenance, and metal fabrication. With the right tonnage, proper operation, and routine maintenance, it provides long-term reliability and precise performance for a wide range of workshop tasks. Choosing a high-quality shop press ensures safer, faster, and more accurate repair results.