TRANSMISSION JACK Manufacturer in China

We manufacture durable and high-capacity TRANSMISSION JACKS engineered for safe removal, installation, and transportation of automotive transmissions. Built with stable frames, adjustable saddles, and smooth hydraulic lifting, our jacks improve workshop efficiency and ensure safer under-vehicle operations.

What We Offer as a TRANSMISSION JACK Manufacturer in China

As a professional transmission jack manufacturer in China, we supply a complete range covering low-profile models, high-lift models, and heavy-duty options for commercial garages. Our products serve automotive workshops, transmission repair shops, car maintenance centers, and tool distributors worldwide.

We provide OEM/ODM solutions for load capacity, saddle design, lifting range, foot-operated pumps, tilt adjustment, paint color, labels, and packaging. Whether you need standard 500kg, 1T, 2T, or customized heavy-duty transmission jacks, we deliver stable and reliable lifting equipment ready for global distribution and brand expansion.

Product List

Services We Provide

TRANSMISSION JACK

OEM/ODM Manufacturing

Customize load capacity, saddle shape, hydraulic pump, tilt mechanism, and appearance.

Branding & Packaging for Distributors

Color customization, logo printing, carton design, manuals, and private-label programs.

Standard & Heavy-Duty Models Available

Wide coverage for workshops, mechanical repair chains, parts suppliers, and tool brands.

Bulk Supply for Global Buyers

Stable production for long-term partnerships and multi-model product lines.

Why Choose Us for TRANSMISSION JACK Manufacturing

Strict Load & Safety Testing

Each jack undergoes tilt stability, lifting accuracy, and load-bearing verification.

Fast Production for OEM Orders

Optimized workshop scheduling ensures short lead times.

Engineering Team for Structural Optimization

Support for frame design, saddle adjustment, and hydraulic system improvements.

Competitive Factory Pricing in China

Reliable performance with cost-effective manufacturing advantages.

After-Sales Spare Parts Support

Hydraulic pumps, wheels, saddles, and casters available for maintenance.

Work With a Reliable Transmission Jack Manufacturer in China

Get stable, safe, and workshop-ready transmission jacks engineered for professional automotive repair.

Frequently Asked Questions

01. What capacities do you offer?

We supply 500kg, 1T, 2T, and custom heavy-duty transmission jacks.

02. Is the saddle adjustable?

Yes. Multi-angle tilt and height adjustments are available for precise alignment.

03. Do you support OEM colors and branding?

Yes. We offer full customization for paint, logo, labels, and packaging.

04. Can the jack be used with any vehicle type?

It is suitable for most passenger cars, SUVs, and light commercial vehicles.

05. What is the lead time?

Usually 20–30 days depending on order size and customization level.

Table of Contents

TRANSMISSION JACK: A Complete Guide for Safe and Efficient Transmission Handling

Product Overview of Transmission Jack

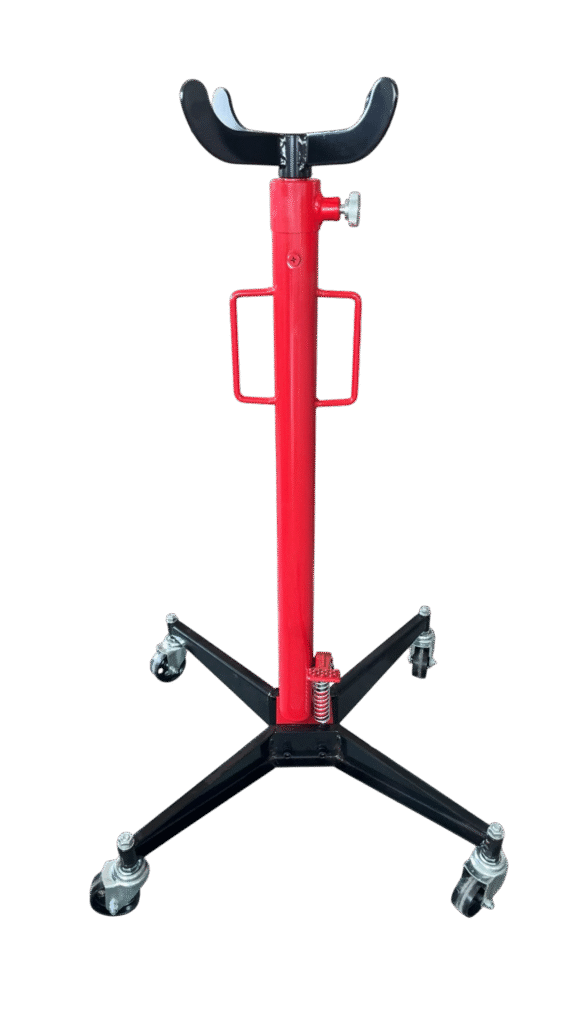

A transmission jack is a lifting tool designed to safely remove, support, and install vehicle transmissions. It provides stability and precision during under-vehicle repair work, improving workshop efficiency and technician safety.

What Is a Transmission Jack?

A transmission jack is a hydraulic lifting device equipped with an adjustable saddle and stable frame used to position and move transmissions during maintenance or replacement. It is widely used in automotive service centers and repair shops.

Types of Transmission Jack

- Low-Profile Transmission Jacks

Designed for quick under-vehicle access on standard lifts.

- High-Lift Transmission Jacks

Suitable for use with two-post or four-post lifts.

- Heavy-Duty Transmission Jacks

For larger transmissions in commercial vehicles and industrial machinery.

- Foot-Operated Transmission Jacks

Allow hands-free operation for improved efficiency.

- Tilt-Adjustable Transmission Jacks

Feature multi-angle adjustment for precise positioning.

Key Features & Advantages

- Stable steel frame for heavy loads

- Adjustable saddle supports multi-angle alignment

- Smooth hydraulic lifting for controlled operation

- Durable casters for easy movement

- Safe and efficient under-vehicle transmission handling

Common Applications

Transmission jacks are used in:

- Automotive repair workshops

- Transmission rebuilding & maintenance shops

- Vehicle service centers and garages

- Fleet maintenance facilities

- Car lift-equipped service bays

How to Choose the Right Transmission Jack

- Lifting Capacity

Choose based on the transmission weight of the vehicles you service.

- Lift Height Range

Match your working environment—floor-level, two-post lifts, or pit stations.

- Saddle Adjustability

More angles enable easier alignment and installation.

- Frame Stability

Wide, reinforced frames improve safety under load.

- Mobility Requirements

Casters and swivel wheels enhance maneuverability.

- Pump Type

Foot-operated systems improve operating efficiency.

Installation & Operation Tips

- Position the jack carefully under the transmission

- Secure the saddle straps before lifting

- Lift slowly for controlled movement

- Keep load centered for maximum stability

- Move the jack only when the transmission is fully supported

- Lower the load gradually after installation

Maintenance & Troubleshooting

Maintenance

- Check hydraulic oil level regularly

- Lubricate casters and moving joints

- Inspect saddle straps and adjustment screws

- Clean after each use to prevent corrosion

Troubleshooting

- Slow lifting → check hydraulic oil or pump seals

- Instability → inspect frame and caster condition

- Tilt issues → adjust saddle screws or tighten bolts

- Oil leakage → replace damaged seals

Safety Considerations

- Never exceed rated load capacity

- Always secure the transmission with straps

- Keep hands clear of moving parts

- Ensure jack is on a flat, stable surface

- Avoid sudden lifting or lowering actions

Conclusion

Transmission jacks are essential tools for safe, stable, and efficient transmission repair and replacement. By choosing the right model and operating it correctly, workshops can significantly enhance technician productivity and reduce risks during under-vehicle operations.