VEHICLE POSITIONING JACK Manufacturer in China

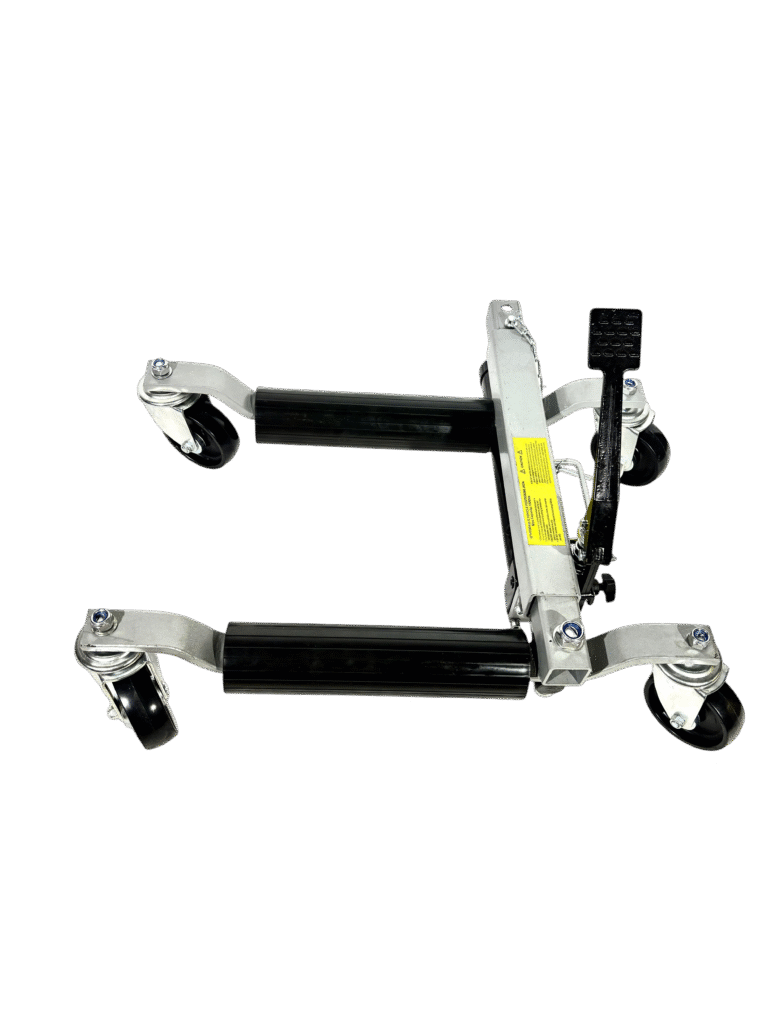

We supply high-strength VEHICLE POSITIONING JACKS designed to move vehicles easily in tight workshop spaces. With durable frames, smooth hydraulic lifting, and 360° casters, they help technicians reposition cars without starting the engine—ideal for repair shops, detailers, and storage facilities.

What We Offer as a VEHICLE POSITIONING JACK Manufacturer in China

As a professional vehicle positioning jack manufacturer in China, we provide standard and heavy-duty models suitable for passenger vehicles, SUVs, and small commercial vehicles. Our jacks support sideways and multi-directional movement, allowing workshop teams to optimize working space and handle vehicle rearrangement efficiently.

We offer OEM/ODM customization for load capacity, wheel material, hydraulic system, pedal design, paint color, branding, and packaging. Whether you require jacks for car dealerships, automotive workshops, detailing centers, or tool distributors, we deliver reliable and cost-effective equipment ready for global distribution.

Product List

Services We Provide

VEHICLE POSITIONING JACK

OEM/ODM Customization

Load rating, wheel material, hydraulic style, color, logo, and packaging.

Bulk Wholesale Supply

Reliable manufacturing for long-term partnerships and fleet customers.

Why Choose Us for VEHICLE POSITIONING JACK Manufacturing

Rigorous Structural Strength Testing

Each jack is tested for chassis contact safety, lifting stability, and caster durability.

Fast Lead Times for OEM Orders

Optimized manufacturing ensures timely large-volume production.

Engineering Support for Wheel & Structure Optimization

We help improve mobility, load capacity, and frame strength based on your market needs.

China Factory Pricing for Global Buyers

High value, strong performance, and cost-effective product lines.

Full Spare Parts Support

Hydraulic parts, wheels, pedals, and pads available for long-term maintenance.

Partner With a Reliable Vehicle Positioning Jack Manufacturer in China

Improve workshop efficiency with durable, easy-to-operate positioning jacks designed for professional garages.

Frequently Asked Questions

01. What load capacities do you offer?

Common capacities include 450kg, 600kg, and 680kg per jack, with custom options available.

02. Can the jack move a vehicle sideways?

Yes. 360° swivel casters allow smooth movement in any direction.

03. Does it damage tires or rims?

No. Soft contact pads protect the tire surface and wheel structure.

04. Do you offer OEM color and branding?

Yes. We support custom color coating, logo printing, labels, and packaging.

05. What is the standard lead time?

Usually 20–30 days depending on order quantity and customization.

Table of Contents

Vehicle Positioning Jack: A Practical Guide for Modern Workshops

Product Overview of Vehicle Positioning Jack

A vehicle positioning jack allows technicians to lift and move a vehicle in any direction without starting the engine. It is widely used in garages, detailing centers, showrooms, and storage facilities where space optimization is essential.

What Is a Vehicle Positioning Jack?

A vehicle positioning jack is a hydraulic device that lifts the car by the tires and allows sideways or 360° movement. With swivel casters and a strong frame, it helps technicians reposition vehicles quickly and safely.

Types of Vehicle Positioning Jack

- Hydraulic Vehicle Positioning Jacks

Most common type; pedal or hand-operated hydraulic lifting.

- Mechanical Screw Vehicle Positioning Jacks

Use mechanical adjustment instead of hydraulic; often cost-effective.

- Heavy-Duty Positioning Jacks

For larger vehicles including SUVs and light commercial vans.

- Professional Garage Positioning Sets

Packaged in sets of four for full-vehicle movement.

Key Features & Advantages

- Smooth hydraulic lifting

- 360° caster movement

- Safe tire-contact lifting pads

- Durable steel structure

- Space-saving and highly efficient in crowded workshops

Common Applications

Vehicle positioning jacks are used in:

- Automotive repair shops

- Body shops and painting centers

- Car detailing studios

- Vehicle storage warehouses

- Car dealership showrooms

- Narrow workshops with limited mobility space

How to Choose the Right Vehicle Positioning Jack

- Load Capacity Per Jack

Match the weight of the vehicle categories you handle.

- Lifting Range

Ensure it fits the tire size and vehicle clearance.

- Caster Quality

Industrial casters improve mobility under heavy load.

- Frame Strength

Choose models with reinforced steel construction.

- Hydraulic vs. Mechanical

Hydraulic = easier operation; mechanical = low maintenance.

- Frequency of Use

Heavy-duty models recommended for daily commercial use.

Installation & Operation Tips

- Place the jack under the tire center

- Pump slowly for smooth lifting

- Secure all four wheels before moving the vehicle

- Ensure the floor surface is flat and clean

- Move the vehicle slowly using both hands

Maintenance & Troubleshooting

Maintenance

- Lubricate casters regularly

- Check hydraulic oil level

- Clean pads and remove debris

- Inspect frame welds and fasteners

Troubleshooting

- Hard to lift → check hydraulic oil

- Caster stuck → lubricate or replace wheel

- Uneven lifting → adjust jack placement

- Oil seepage → replace pump seals

Safety Considerations

- Never exceed rated load capacity

- Avoid moving the vehicle on uneven flooring

- Keep feet and hands clear of casters and moving parts

- Use jack sets of four for full-vehicle repositioning

- Do not leave the vehicle lifted unattended

Conclusion

Vehicle positioning jacks greatly improve workshop space management and technician efficiency. With safe lifting, smooth movement, and versatile applications, they are essential tools for modern automotive service environments.