Pneumatic Pump manufacturer

DonLi supplies durable and stable pneumatic pumps designed for hydraulic rams, porta power kits, shop presses, and heavy-duty garage equipment.

Our pumps deliver consistent air-driven pressure, require low maintenance, and are built for long, reliable service in professional workshops.

What We Offer as a Pneumatic Pump Manufacturer in China

As a professional pneumatic pump manufacturer in China, we support both OEM and ODM production, allowing customers to develop market-ready hydraulic and pneumatic solutions with full engineering support.

We help:

- Brands and importers develop private-label pneumatic pumps with custom colors, logos, and packaging.

- Distributors and wholesalers expand their product lines with stable-quality, factory-priced pneumatic pumps.

- Tool companies and garage equipment suppliers create upgraded versions that meet specific regional standards or market demands.

Whether you need customized specifications, improved performance, or bulk wholesale solutions, we deliver reliable pneumatic pumps designed for global B2B applications.

Product List

Advantages and Features

Pneumatic Pump – Key Features & Advantages

Fast & Consistent Power Output

Delivers steady force for lifting and pressing tasks, helping technicians finish jobs faster with fewer interruptions.

Built to Withstand Heavy Daily Use

Engineered with durable components to handle high-frequency workloads in busy workshops without performance drop.

Lightweight & Technician-Friendly

Easy to move, easy to connect, and easy to operate—ideal for teams that need efficiency and mobility on the job.

Fits Multiple Garage Tools & Scenarios

Works seamlessly with porta power kits, jacks, presses, and repair tools, giving buyers one pump for multiple tasks.

Why Choose Us for Pneumatic Pump Manufacturing

Precision Quality Control for Every Pneumatic Pump

As a professional pneumatic pump manufacturer, we apply strict inspection standards to ensure stable output, long lifespan, and consistent performance in real workshop environments.

Fast Lead Times Backed by Strong Production Capacity

Our factory maintains stable material supply and automated assembly lines, allowing us to deliver OEM pneumatic pumps quickly and reliably for large or urgent orders.

Efficiency-Driven Pump Engineering

We design each pneumatic pump to reduce technician workload, speed up lifting and pressing tasks, and minimize downtime for your end users.

Full OEM/ODM Customization Services

As a China-based pneumatic pump supplier, we support custom colors, logos, specifications, pressure levels, and packaging—helping brands build unique product lines for their markets.

Custom Development for Market-Specific Needs

We work closely with distributors, tool brands, and equipment companies to develop custom pneumatic pump solutions that fit regional standards and application demands.

Grow Your Brand With

Our Pneumatic Pump Manufacturing Expertise

High-performance pumps built for your market needs.

Frequently Asked Questions

01.What certifications do your garage equipment meet?

Donli products comply with major international standards, including CE and ANSI/ASME.

Every batch goes through load testing and detailed quality inspections, and our factory operates under a certified ISO quality management system to ensure safety and consistency.

02.Can Donli support mixed orders for different equipment

Yes. We fully support mixed container loading.

You can combine floor jacks, engine stands, shop presses, hydraulic tools, and other models in a single shipment to reduce your purchasing cost and simplify replenishment.

03.Do you offer spare parts and long-term maintenance support?

Yes. Donli keeps a complete stock of seal kits, hydraulic cylinders, pumps, valves, wheels, and handle components.

We also provide long-term after-sales support, including troubleshooting videos and technical guidance to keep your equipment running smoothly.

04.What is your average lead time for bulk orders?

Our typical lead time is 25–30 days for bulk orders, depending on the quantity and product types.

During peak seasons, we arrange production in advance, and urgent orders can be prioritized to help keep your inventory stable.

05.Can you customize equipment specifications for our market?

Absolutely. Donli offers full OEM/ODM customization, including:

Custom colors

Private logo and packaging

Different load capacities (1–50 tons)

Reinforced structures and market-specific designs

We can follow your drawings or requirements to create a product that fits your local market perfectly.

Table of Contents

Pneumatic Pump:

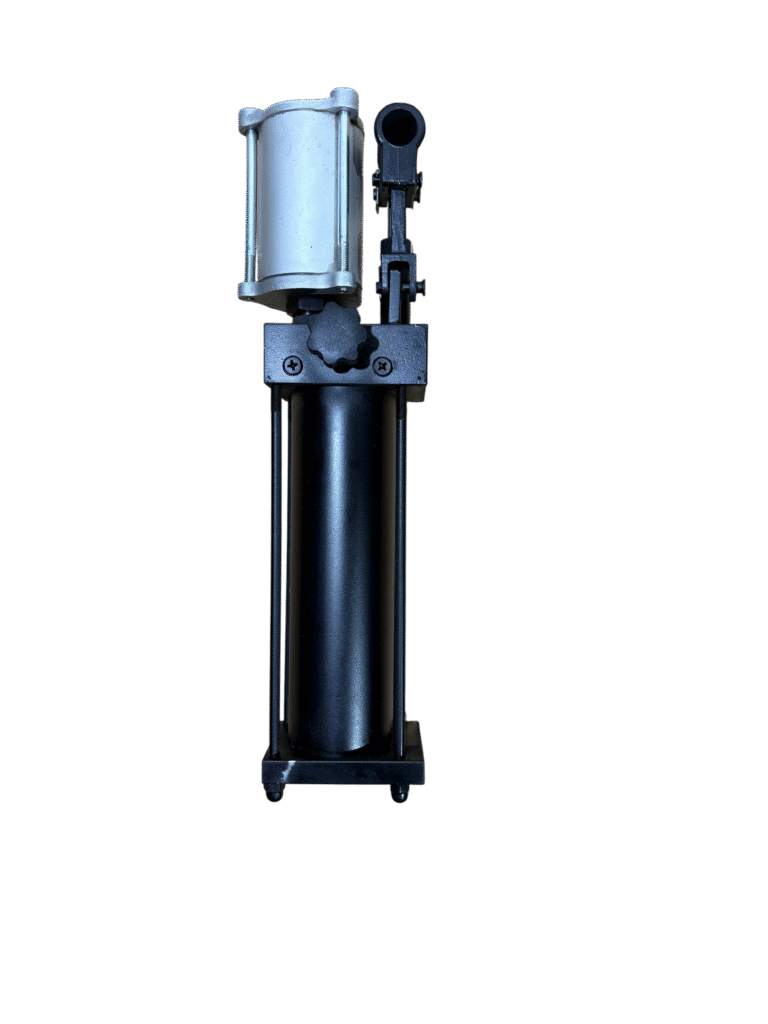

A pneumatic pump is one of the most reliable power sources used in automotive workshops, hydraulic repair centers, and industrial maintenance facilities. It converts compressed air into hydraulic pressure, allowing technicians to lift, push, press, or straighten components with minimal effort. If you work with rams, porta power kits, or shop presses, understanding how a pneumatic pump works can help you choose the right model and achieve better performance in daily operations.

What Is a Pneumatic Pump and How It Works

A pneumatic pump is an air-driven hydraulic pump. Instead of using manual force or electricity, it uses compressed air to generate hydraulic pressure. When air enters the pump, it drives the internal air motor, which then forces hydraulic oil through the outlet. This creates the pressure required to operate cylinders, rams, and hydraulic tools.

The process is simple, efficient, and ideal for environments where continuous, high-output pressure is needed without heavy electrical equipment.

Types of Pneumatic Pumps

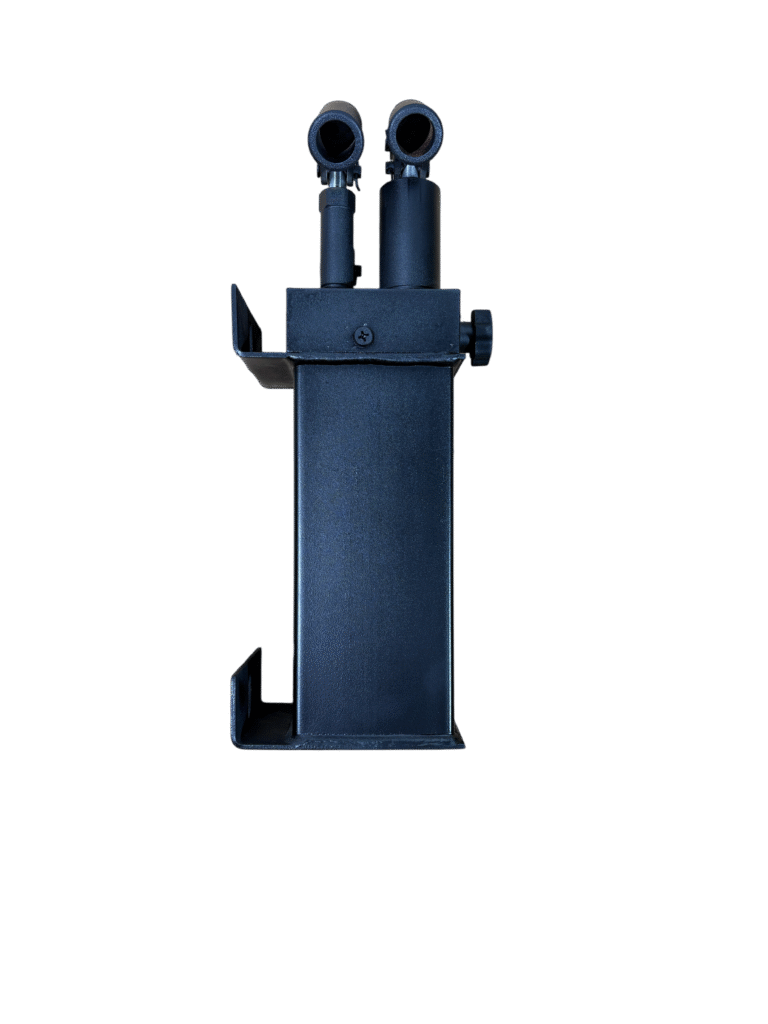

Pneumatic pumps are available in several configurations:

Single-acting pneumatic pumps – Provide pressure in one direction, suitable for simple lifting or pushing applications.

Double-acting pneumatic pumps – Deliver pressure in both directions, making them ideal for more precise industrial tasks.

High-pressure pneumatic pumps – Built for demanding applications such as frame straightening or heavy-duty shop presses.

Foot-operated pneumatic pumps – Common in automotive repair where hands-free operation improves efficiency.

Each type matches different workshop needs and helps technicians complete tasks faster and more safely.

Types of Pneumatic Pumps

Pneumatic pumps are available in several configurations:

Single-acting pneumatic pumps – Provide pressure in one direction, suitable for simple lifting or pushing applications.

Double-acting pneumatic pumps – Deliver pressure in both directions, making them ideal for more precise industrial tasks.

High-pressure pneumatic pumps – Built for demanding applications such as frame straightening or heavy-duty shop presses.

Foot-operated pneumatic pumps – Common in automotive repair where hands-free operation improves efficiency.

Each type matches different workshop needs and helps technicians complete tasks faster and more safely.

Key Features and Advantages

Pneumatic pumps are popular because they deliver:

Stable air-driven pressure for consistent performance

High output force suitable for heavy-duty tools

Fast response and smooth operation

Low maintenance due to simple mechanical structure

Long service life, even in continuous-use environments

High compatibility with cylinders, porta power systems, and shop equipment

These features make pneumatic pumps a dependable solution for daily professional use.

Common Applications

A pneumatic pump is widely used in automotive and industrial settings, including:

Operating porta power kits for vehicle frame straightening

Powering hydraulic rams and cylinders

Driving shop presses for bearing installation or component pressing

Supporting transmission or engine repair tasks

Providing controlled pressure for industrial maintenance equipment

Its ability to deliver consistent hydraulic force makes it essential in any workshop that handles lifting, pushing, bending, or pressing operations.

Pneumatic Pump vs. Manual and Electric Pumps

Compared with manual pumps, pneumatic pumps require far less physical effort and operate much faster.

Compared with electric pumps, they are simpler, easier to maintain, and safer in environments with oil, dust, or flammable substances.

For most automotive workshops, pneumatic pumps offer the best balance of speed, durability, and cost-effectiveness.

How to Choose the Right Pneumatic Pump

When selecting a pneumatic pump, consider:

Required pressure output (PSI or bar)

Oil reservoir capacity

Compatibility with your cylinders or hydraulic tools

Air pressure available in your workshop

Frequency of use and work intensity

Noise level and response speed

Choosing a pump that matches your actual workload ensures better performance and longer equipment life.

Installation & Operation Tips

Using a pneumatic pump is straightforward, but proper setup is important:

Ensure the air supply is clean and stable

Check oil levels before operation

Use correct connectors and hoses

Avoid exceeding recommended pressure

Release pressure properly after each task

Following these steps helps maintain safe and efficient operation.

Maintenance & Troubleshooting

Pneumatic pumps require minimal maintenance. The most common checks include:

Inspecting seals and hoses for wear

Ensuring clean air input to prevent contamination

Checking for pressure loss

Monitoring oil levels and potential leaks

Common issues such as weak pressure or slow operation often relate to air supply problems or worn-out sealing components and can be resolved with simple adjustments.

Safety Considerations

Always operate pneumatic pumps within the recommended pressure range.

Avoid using damaged hoses, keep the workspace clean, and ensure all connections are secure before pressurizing the system. Proper safety practice not only protects the equipment but also prevents workshop accidents.

Conclusion

A pneumatic pump is a powerful, reliable, and efficient tool for any workshop that requires consistent hydraulic pressure. Its simple structure, high durability, and strong performance make it a preferred choice for lifting, pressing, and equipment repairing tasks. Understanding how the pump works—and how to select the right model—ensures you get the best long-term value from your workshop equipment.